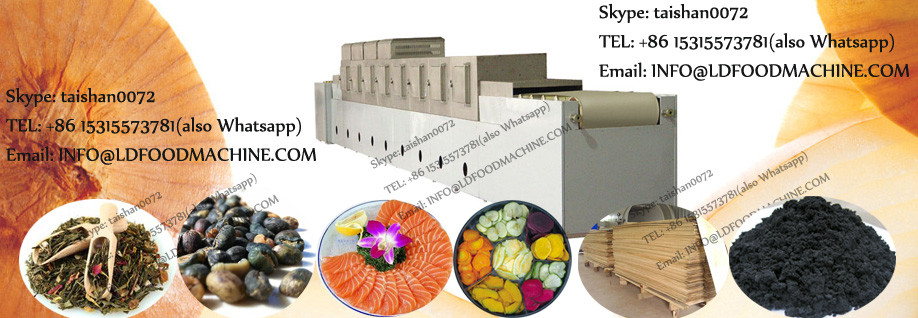

Hot Sale XSG-12 Rotary Flash Dryer with good quality

Rotary flash dryer is a new high efficient fluidized drying equipment that we designed for solve the static drying’s low efficiency and high consumption problem. When designing the equipment, we combined the features of air stream drying and fluidized drying together. So the machine has reasonable structure and good performance, it really achieves the aim of low consumption and high efficiency of fluidizing drying.

This machine has a wide application scope, it can be used for drying in fire retardant, molecular sieve, rubber and plastic assistance, pesticide, pigment, dyestuff, fine chemicals, feedstuff, pharmaceutical and part intermediate industries.

Hot air enters the stirring, crushing and drying chamber in a certain speed from the air inlet that at the bottom of dryer and produces vigorous eddy airflow. Material is acted by centrifugal force, shearing force, impact and friction, the particle size of material becomes very small and mass and heat transmission is strengthened. At the bottom of dryer, big damp granules is crushed, small and low moisture content granules rise with the rotating air stream. During the rising process, the granules are dried further. Because of the rotary flow of air and solid, inertia of solid phase is higher than gaseous phase, the relative speed of air and solid is big, it strengthens mass and heat transmission, so drying intensity is high.

Features

1.Several feeding device can be chose,feeding is continuous and stable,no phenomenon of bridging.

2.There is special cooling device at the bottom of dryer,it can avoid the material that in the bottom high temperature area be bad.

3.There is special air sealing device and cooling device for bearing, it can make the life of transmission part longer effectively.

4.There is special air distributing device, it can reduce the resistance of equipment, and make the air speed in drying tower become balance.

5.There is classify ring and turbojet plate, the fineness and final moisture of product can be adjusted and controlled.

6.Circumference air speed in the drying tower is high, the residence time of material is short, it can avoid the material stick on the wall and thermal sensitive materials go bad.

Technical parameters

More details ,please contact me freely by email.

Or sending inquiry to me .

Thanks and best regards.