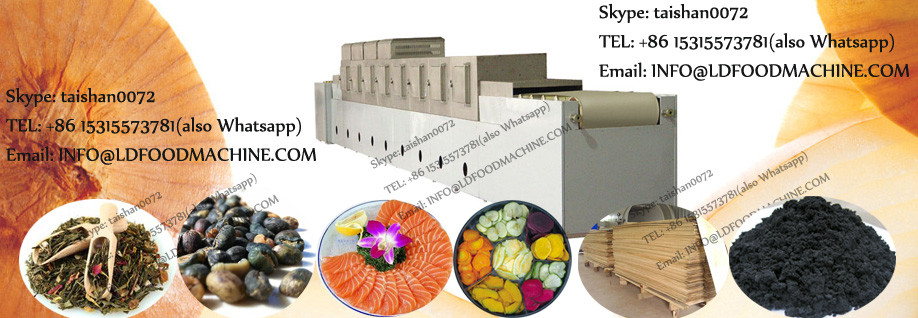

Microwave atmosphere furnace for Powder metallurgy, carbide sintering

Summary

PT-QS Microwave atmosphere furnace is suitable for oxygen atmosphere,inert atmosphere,reducing atmosphere,

calcination ,sintering,and synthesis etc.

Technical Specifications

Project |

PT-QS1516 |

|

Power |

Voltage |

380±10V 50Hz 3 phase |

Rated power |

4KW |

|

Microwave system |

Microwave output power |

0.1~1.4kW Adjustable |

Microwave frequency |

2.45GHz±25MHz |

|

Insulation System |

Limiting temperature |

1600℃ |

Working temperature |

1550℃ |

|

Sintering space |

125mm×125mm×65mm(D×W×H) |

|

Temperature control system |

Temperature testing method |

Infrared thermometer or thermocouple |

Temperature testing range |

300-1800℃ or 0-1600℃ |

|

Temperature control accuracy |

Reading ±0.1% |

|

Atmosphere system |

Static ultimate vacuum degree |

≤100Pa |

|

Two vacuum unit, two rods atmosphere control line |

Can input oxidizing gas,inert gas, reducing gas, vacuum, etc. |

|

Control system |

PLC,7 inch touch screen |

40 segment of process parameters can be set up with data storage, export experimental data; can be manual, automatic temperature control mode, real-time curve display |

Microwave shielding system |

Microwave shielding and alarm |

Microwave shielding device |

Portable microwave leak detector, online alarm | ||

Microwave leakage levels |

2 |

|

Cooling system |

High accuracy cooling system |

Flow >2m3/h,pressure 0.08-0.2MPa |

Outside dimension |

Main parts |

1150×850×800mm (L×W×H) |

Cabinets | ||

Floor space |

1m2 |

|

III.Application range

This product is mainly used for calcining materials / synthesis process and experimental study of small batch

production. The main application areas are as follows:

1)Metal carbide, nitride, oxide material reduction / roasting / calcination / synthesis / sintering;

2)Sintering of battery materials;

3)Sintering of catalytic material

4)Sintering of various ceramic materials

5)Rare earth fluorescent materials synthesis / Sintering;

6)Powder metallurgy, carbide sintering;

7)Vacuum sintering of magnetic materials.

IV.Main features

1)The use of special industrial microwave sources to ensure continuous and stable

operation of the device for a long time, the microwave output power stepless

adjustable, high-precision direct measurement of the sample temperature infrared

thermometer to achieve precise control of the technology curve;

2)Equipped with an embedded computer control systems, real-time temperature,

power display and storage of records at any time, the heating process of dynamic

monitoring of the technology curve and ready to adjust the process parameters,

with manual, automatic, heated three operating modes, and can freely switch;

3)Heating speed, temperature uniformity, no thermal inertia;

4)Various specifications, models of special crucibles and insulation structure for

selection of non-polluting materials;

5)Road with two vacuum unit and atmosphere control line;

6)Into and out of the gas channel is individually designed, high vacuum and

atmospheric conditions of options to meet the requirements of different processes

of the atmosphere;

7)Machinable handle a variety of microwave properties of different materials,

common good;

8)Safe and reliable microwave shielding design, multiple anti-leak protection.

Microwave vacuum furnace

Microwave tube furnace

Company information

Zhengzhou Protech Mechanical Equipment Co.,Ltd.-owned by Protech(China) Holding Limited,is founded by a group of technology enthusiatic people who are devoted toProviding the newest technology and innovation in different fields,and serving various clients worldwide for it’s applications.

Our products mainly include laboratory and industrial high temperature furnace and heating elements.Like dental furnace,muffle furnace,tube furnace,dental furnace,vacuum furnace,atmosphere furnace,gold melting furnace CVD/PECVD system, Microwave furnace etc.We have our own manufacturing base factory as while as many sub-contracting factories,Which enable us a reliable manufacturing ability and quality control system.

Contact :Anna Liu

Skype:protechsales03

Mob.:86-18137195605

Tel:86-0371 67103035

Email:Anna(@)lab-furnace.com

QQ:546934872