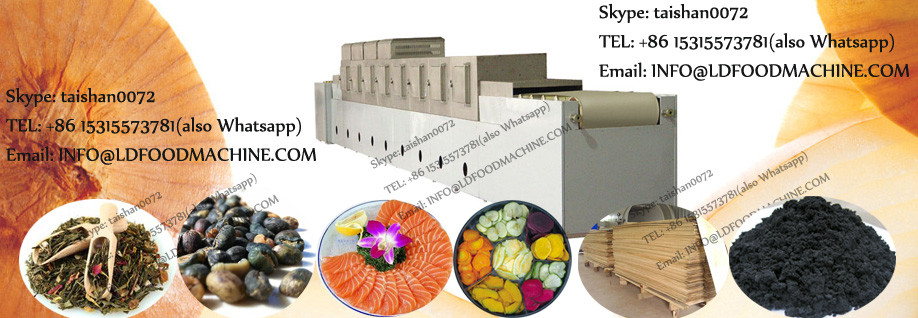

Electrofacing water sewage sludge Hollow Blade Drying machine

Product Description

Description

Hollow Paddle Dryer is a horizontal stirring and heat conduction type drying equipment that can work continuously. Its stirring blade is like ship paddle, so it is called paddle dryer. In foreign countries, it is also called slot dryer or stirring dryer.

Needed heat of the dryer relies on heat conduction to heat indirectly, so during the drying period it doesn't need air or just need little air to take the moisture away. It greatly reduces the heat loss that takes away by air flow and the use ratio of heat is improved, so it is an energy saving type drying equipment. Paddle dryer is widely used in petrochemical, chemical, metallurgy, foodstuff, pharmaceutical, pesticide industries and so on for drying powder, granules, filter cake and seriflux materials.

On the basis of a wide research, absorption and digestion of domestic and foreign advanced technology, Jiangsu Xianfeng Drying Engineering Co.,Ltd improved andoptimal designed the wedge hollow paddle dryer. It can indirectly heat or cool paste shape, granules, powder and seriflux materials. It can achieve the operation of drying, cooling, heating, sterilization, reaction and low temperature calcinations, etc. In the equipment, the wedge-shape stirring and heat transfer paddle has high heat transfer efficiency and the heat transfer surface self-clean function.

Principle

The heat transfer surfaces of hollow paddle dryer include paddle, stirring shaft, and wall surface. And the heat transfer area of paddle is the great majority, so the structure of the equipment is compact and heat transfer area of unit volume is high. Stirring and mixing make the material turn over tempestuously so that the material can get high heat transfer coefficient, the occupied area and space is small and the plant capital cost is saved. Because the structure of paddle is special, during the drying period, material will be extruded and loosed, drying is strengthened. Loading ratio of drying chamber is high, it can be 80%-90%, drying time can be regulated from a few minutes to a few hours by regulating the feeding speed, the rotary speed of stirring shaft and the loading ratio. And from feeding port to discharging port the movement of material is basically piston motion. Its residence time distribution is narrow, so the moisture of product is uniform. The paddle that on the stirring shaft has a certain axial direction, so it can dry material continuously.

Structure

Take double shafts type for example to introduce the structure (paddle dryers include single shaft, double shafts, and four shafts). It consists of W-shape shell with jacket, upper cover, two hollow shafts with paddles, covers of two ends, swivel joint, flexible metal tube and transmission mechanism that including gears and chain wheel, etc.

The cores of the equipment are the two hollow shafts and the hollow paddles welded on the shafts. The shape of paddle is wedge-shape hollow hemicycle, inside it can input heating medium. Except the stirring function, it also is the heat transfer device. Two main heat transfer surfaces of paddle are slope surfaces. When material contacts with the slope surface, granules will slip away from the slope surface with the rotary of paddle. The heat transfer is renewed continuously, so the heat transfer is strengthened. At the triangle bottom of paddle there is scraper blade, it can sweep the material that deposit at the bottom, so it can avoid the dead corner.

There are some requirements for the distribution of paddle and the size of its each part. And at the feeding area, drying area and discharging area, there are not only paddles but also complementary unit, it can ensure the machine works stably, and dry uniformly. Moreover, residence time can be regulated.

Company profile:

Xianfeng Drying is a large enterprise in China dryer industry and owns an import&export license. It has passed the ISO9001:2008 quality management system and ISO14001:2004 Environment Management system.

Now our products sell all over the world and have been exported to USA, Israel, Brazil, South Africa, Japan, Sudan, South Korea, Thailand, Vietnam. Indonesia, Philippines and so on.

After-sell service:

All our machines guaranteed for trouble free performance for a period of 12 months from commissioning in buyer place.

Installation, commissioning, training for buyer's technicians and other after sell service all for free.

The buyer shall bear all expenses incurres in the trip of sell's delegation for erection, commissioning and training, including air tickets, meal, hotel accommodation and local transportation.