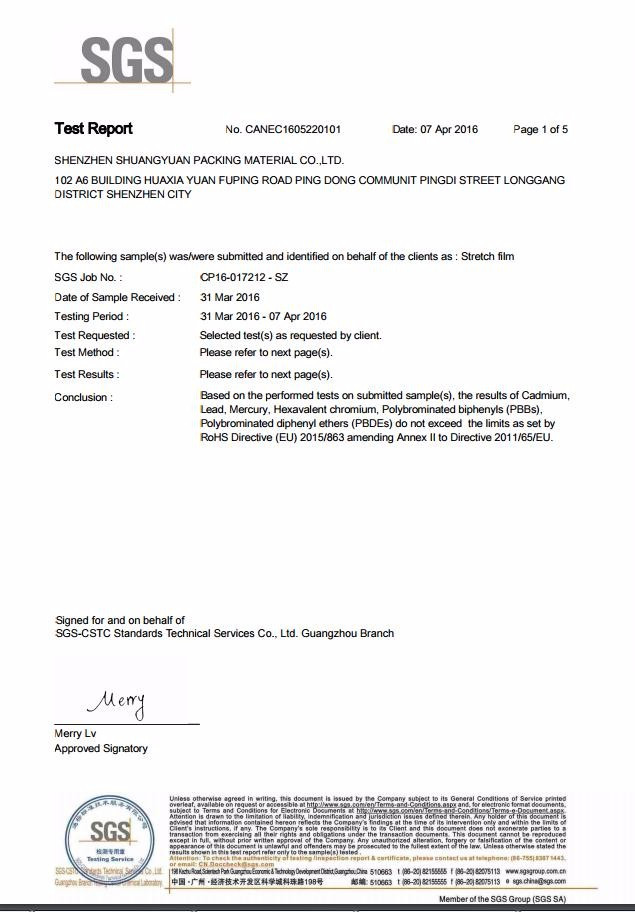

Fresh LD Cooling machinery

![Commercial Farm fresh LD cooling machinery]()

Overview the LD cooling machinery:

The LD cooling machinery applies LD cooling technique,which use the LD pump to pump the air and steam out of the LD tank so as to lower the inner room pressure and temperature.

In the low pressure,the water’s boiling point is cut down,steam generate rate speed up.

These conditions take the heat both the food and environment’s away so as to cool the food better.

![Commercial Farm fresh LD cooling machinery]()

Characters:

1.The full-automatic control system makes the operation more simple.The full-automatic control system is controlled by paint(Programmable Logical Controller).paint simplifies the control operation so all the data can be input,output,print and conserved simply.Also it will save a lot of time and improve the output.

2.The device’s operation expense is available because of less electricity power,more containing weight,higher output and lower electricity consumption hourly.

3.The advanced device applies saving-water control box.The box will reduce a large quantity steam consumption so as to cut down a part of expense.

4.The double-opening pushing door can improve the efficiency and avoid the food polluted by operators.

5.The full cooling process is finished in the of LD condition preventing the outer environment polluting the food secondly.

6.The advanced device’s cooling time is LDout 15minutes to lower the temperature from 90℃ to 15℃ below.The shorter the cooling time takes,the fresher the food’s taste is.

7.The dimension of the machinery is reasonable so it will occupy less place.

8.The cooling machinery is environment-friendly.And it doesn’t need periodic maintenance.It’s a very perfect LD cooling machinery.

Technical Parameter:

Item |

Parameter |

Cooling temperature scope |

90~10℃ |

Cooling time |

10~25min |

Handling Capacity |

500Kg/time |

Main material of the cmachineryt |

S304 Stainless Steel |

LLDe of the open door |

Double door |

Cooling water machinery |

Self-contained |

LD pump |

Made in German |

Heat exchanger |

da |

Gross weight |

4T |

![Commercial Farm fresh LD cooling machinery]()